This technique has been adapted by many motorsport competitors and is commonly used on any part that will experience high temperatures.

Benefits of ceramic coating exhaust manifold.

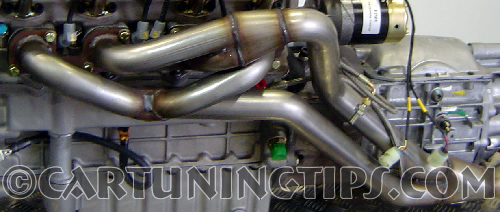

Tungsten grey ceramic coated manifolds.

It is a very durable.

The most advanced exhaust system coating available.

This in turn will mean cooler intake temperatures and more power.

Increase performance reducing the backpressure.

By doing so ceramic coating reduces under hood heat temperatures which will increase horsepower.

We can assert this because it follows that the cooler the under bonnet temperature is the cooler the air.

In other words ceramic coated headers look and function the same on mile one as they do on mile 300 000.

After up to 9 years i have had no negative issues with either the appearance or functionality and plan to use on my current project.

Benefits of ceramic coating your exhaust manifold.

Below are some examples of how ceramic coatings can help increase your vehicles overall performance.

I have used ceramic coating from m r performance coatings in kodak tn on exhaust manifolds on cars from 1915 to 1972.

These coatings prevent corrosion increase durability and provide thermal insulation.

Our ceramic coating is highly effective when used on engine exhaust system components including exhaust manifolds exhaust headers cat boxes turbochargers and tailpipes helping to protect sensitive components from the effects of heat.

In very general terms cooler air means greater potential engine power.

The manifold will live longer.

We will take a look at why so many people are getting ceramic coatings applied to their exhausts.

Ceramic coatings can help improve the performance of your headers turbo parts and exhaust pipes.

Ceramic coating is an excellent thermal barrier.

Exhaust manifold ceramic coating cost.

If you thought the engine gets hot you should see the exhaust parts.

Heat at those levels is enough to do serious damage to internal parts of the vehicle.

They offer a cast iron gray color as well as blacks and bright silver.

Exhaust manifolds can either be a cast iron factory type manifold or a tube steel header typically used in performance applications though they are becoming very common in oem applications.

Ceramic is a highly durable substance that resists corrosion and stands up to a large amount of abuse.

There are a variety of reasons for coating an exhaust manifold header.

Ceramic has high resistance and is very durable.

Ceramic coating is fantastic as a heat insulator and will reduce the surface temperature within the exhaust by up to a third.

Use eastwood high temp exhaust coatings on your vehicle to provide protection in extreme conditions.

A ceramic header coating also provides protection against the corrosive materials in the exhaust.

Even if you are already using a high grade stainless steel or titanium set.