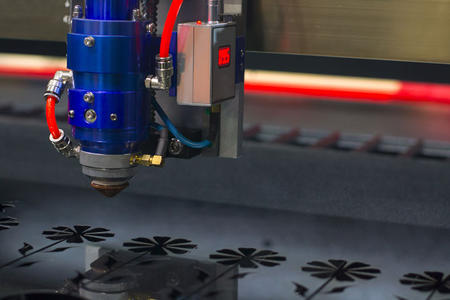

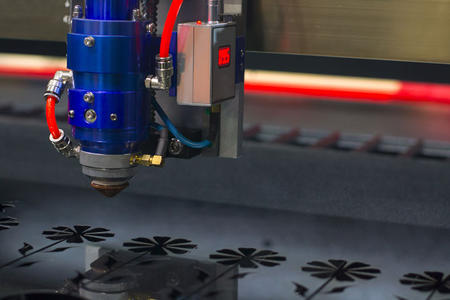

We use technologies as cnc laser cutting and cnc bending.

Bend lance sheet metal laser cut.

Bends in sheet metal are manufactured using sheet metal brakes.

I admit im not an expert with the sheet metal option in solidworks but i have no idea how i can lance little tabs along the length of a u channel i ve created out of sheet metal.

In low carbon steel sheet metal the minimum radius of a bend should be one half the material thickness or 0 80 mm 0 03 inch whichever is larger.

Avail of tremendous export opportunities and competitive prices when it comes to laser cutting and bending welding and other processes.

For the ease of manufacturing multiple bends on the same plane should occur in the same direction.

We are the experts when it comes to laser cutting and sheet metal fabrication.

Sheet size capabilities are up to 3000mm x 1500mm.

We cut bend weld metal sheet for you.

Bends specified as angles may be toleranced at plus or minus one half degree at a location adjacent to the bends.

Our 4kw co2 laser and 2kw fibre optic laser is capable of cutting sheet metal plates ranging between 0 5mm and 25mm in thickness in a variety materials such as stainless steel mild steel aluminium and galvanised sheet just to name a few.

Sheet metal fabrication aluminium steel.

Cutting of the shape of the flat metal sheet executed with cutting machines such as laser cutting oxygen lance cutting or punching.

Bending in the specific areas of bends which requires specific machines and processes as bending and roller leveling according to the type of bend to be realized.

A 1 degree tolerance on all bend angles.

The bystronic xpert press brake provides precision bending results coupled with superior repetition accuracy allowing us to provide you with parts that meet your exact specifications quickly and cost effectively.

We provide metal cutting services for the fabrication of parts out of sheet metal.

Sheet metal parts with a minimum of 0 9mm to 20mm in thickness can be manufactured.

The automated cutting processes guarantee high precision and quality of ready parts.

Avoid large sheet metal parts with small bent flanges.

When designing parts for laser cutting one should not make holes smaller than the thickness of the material.

Laser cutting company offers custom metal forming services for laser cut parts using the bystronic xpert 150 press brake.

Bends should be toleranced plus or minus one half degree at a location adjacent to the bends.